DMK

The DMK is a compact and powerful measurement solution designed for inverter-driven motors.

It precisely measures phase currents and PWM-voltages and perfectly synchronizes them to the rotor position, providing real-time visualization and data storage.

With its integrated functionalities, DMK simplifies motor analysis, making it an essential tool for development, benchmarking and endurance tests.

Beyond its core capabilities, the DMK replaces multiple laboratory instruments. This not only saves cost and space but also delivers measurement results specifically tailored to motor control applications, making it an all-in-one solution for engineers.

HMI

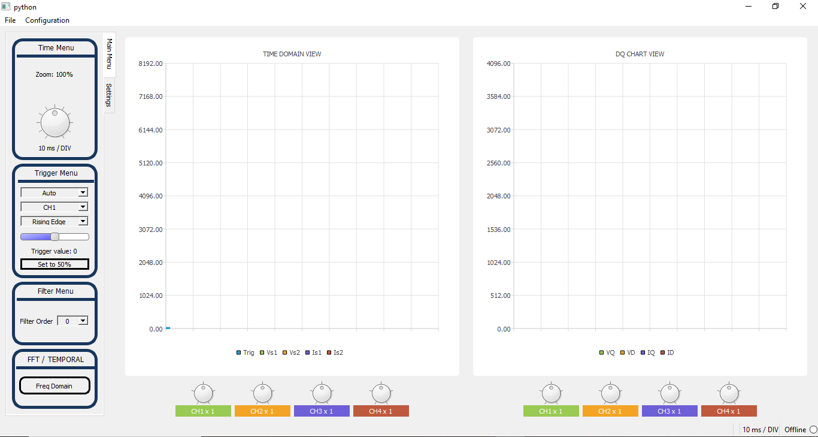

Visualisation Interface

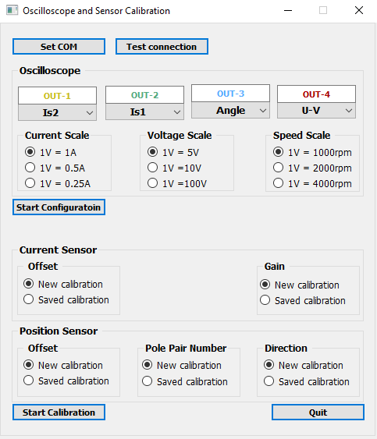

Configuration Interface

The Usage of DMK

Spécifications

| Default configuration | Possible configuration | |

|---|---|---|

| Power Supply | USB-C | |

| Battery | 4000mAh | |

| Input | From Inverter (3 Phases) | |

| Output | To Motor (3Phases) | |

| Maximum Current (Inverter) | 15 Amp | 1 Amp – 200Amp |

| Max Votage (Phase to Phase Inverter) | 400V Peak | 20V-400V Peak |

| PWM Frequency Max | 20kHz | 4-40kHz |

| Encoder type | Incremental A,B,Z | Incremental (ABZ), SPI, … |

| Isolation | 600V | 600V |